There are various types of gears available on the lookout, produced by material, shafts, measures, all planned relying upon its motivation. There are various measures used to group each kind of gear, a famous technique is sorting them as per the game plan of shaft or axle. There are for 3 sorts of shaft plan, to be specific equal shafts, crossing shafts and non-converging or non-equal pivot. Prior to sending off to additional conversation however, let me initially characterize a ‘gear’. In layman’s term, a gear is a circularly molded toothed wheel that serves as a system to communicate responding or rotational movement starting with one piece of a machine then onto the next. Besides when there are at least two gears working with one another the association between these gears permits power stream starting with one gear shaft or axle then onto the next.

To start with, equal shaft gears are the kind of gears that interlock in a similar surface level. Models are spike or straight-cut (easiest sort of gear), helical (basic helical gear and herringbone or twofold helical gear). They work as an instrument to move force of rotational movement between the equal shafts. The advantages are these gears provide most extreme torque intended for long haul productivity. Likewise, it can convey a high burden and does not make a lot of commotion when it works. Then again, creation of these sorts of gear is expensive and makes hub push. These gears are by and large utilized for machines with manual transmissions like clock, vehicle directing and the sky is the limit from there. Second, converging shaft gears are intended to permit smooth exchange of force and movement between tomahawks that are calculated to be opposite with one another. Coming up next are sorts of gears that fall into this classification: bevel miter, straight bevel, winding bevel and zero bevel or zero, coniflex, precise and crown gear. Their design is to drive machines that require speed and strength since it can deal with high burden limit.

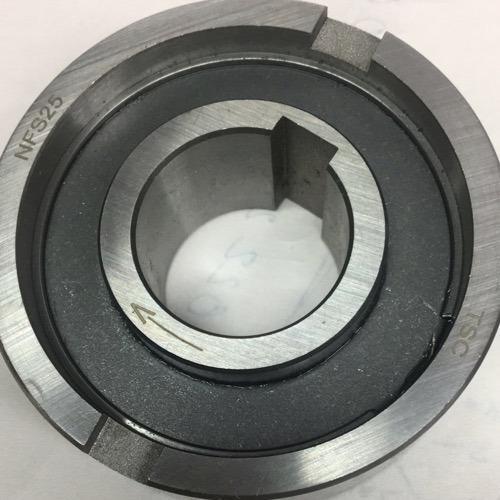

Ultimately, non-crossing or non-equal ruedas libres shaft gears are utilized on applications that require high-proportion speed decrease that can provide power transmission inside a restricted region while utilizing gears with non-converging tomahawks. In spite of the fact that it is the most inexpensive kind of gear, on the grounds that its creation cost is likewise the least, it has a restricted burden capacity. This mishap can be effortlessly solved by bringing the proportions down to increment effectiveness. Instances of nonintersecting shaft gears are crossed-helical, worm and hypoid. These are usually seen on traveler lifts, electric blender, sprinkler, back axles of transports and other heavy vehicles among others. This is just a single numerous frameworks that orders the utilization of gears. Some classifies gears agreeing pitch measurement, materials used to produce the gear, fabricating accuracy, number of steps and lodging plan among others.