CNC programmers who employ dynamic toolpaths can get top-quality results while also decreasing the air cutting time as well as cycle time. This can also increase your machine’s use.

PSO uses a social algorithm for finding optimal routes that balance exploration (searching in new regions) as well as consumption (refining well-known solutions) as similar to birds’ flocks or schools of fish.

Efficiency Strategies

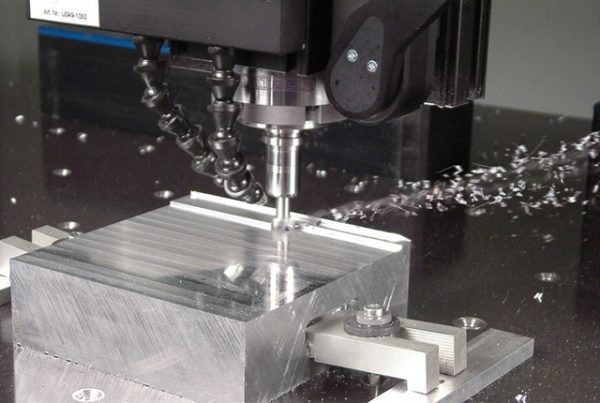

Using an unoptimized tool path so that the machine spends longer cutting every part that is needed. It will also wear out faster, consume much more energy, and will have a less long life. A toolpath optimized specifically for the task can guarantee that only the needed amount of material is cut. The cycle duration and energy consumed are reduced.

A third factor to consider is the possibility of reducing force deflection. This can help prevent injury to the machine and reduce the overall quality of the product. For this purpose there are a myriad of methods that are employed.

Genetic algorithms, for example Adaptive Convergence Optimization (ACO) and Particle Swarm Optimization (PSO) make use of concepts of natural selection and evolution to maximize the use of tools by merging and developing pathways that work well. They are often able to create efficient tools for complex geometries which would be difficult to tackle by other techniques. ACO and PSO can also detect problems that arise from the positioning (e.g. fast movement that damages the materials in-process) and slow down the movements in order to conform to programmed rate of feed, to ensure the safety of the machine.

Optimizing Toolpaths

There are a variety of optimization methods that could be utilized to boost efficiency, reduce costs and enhance precision. Optimizing your tool paths dynamically helps you meet your targets, regardless of whether you want to increase cycle times surfaces, finish finishes, or even the lifespan of your spindle.

They employ iterations or “generations” to find to find the most effective routes for your specific CNC machine. They take into account the parameters and cat kim loai cnc machining conditions that your machine has to select the optimal path for your job.

The algorithms are taught by interfacing with the machine’s environment and adjusting toolpaths while they work and improving over time. The algorithms are able to adapt to changing conditions in the actual process of machining, which results in a more efficient overall toolpath. This improves productivity and durability of aerospace as well as medical parts. Also, it increases the efficiency of machining by reducing the tool’s power consumption. This saves businesses money as well as enables them to present quotations that are competitive the industry in which prices are subject to change.

Techniques

CNC machining is a complex process that can be labor-intensive, however advancements in optimization of the toolpath are making the process faster and more accurate. With the help of various algorithms such as genetic algorithms, ant colony optimization, particle swarm optimization, and deep learning, manufacturers can attain unprecedented levels of efficiency and precision.

Innovative Algorithms

Genetic algorithms employ the notions of natural selection to determine the most effective paths for tools, adjusting the path as it goes along to improve on the previous version. ACO and PSO as swarm intelligence algorithms, use patterns of behavior in swarms, like that of fish schools and birds, to improve a path. These algorithms are excellent at balancing exploring and exploitation. This is perfect for dynamic environments like machine shops.

The toolpath is optimized by reinforcement learning. The process concentrates on a specific goal such as reducing the force on the cutter and getting rid of the over-cut. The algorithms are able to gain knowledge from studying data, interacting with the machine environment and constantly improving toolpaths by analyzing feedback from the real-time.

Benefits

Using CAM software to optimize tools can lead to significant improvements in machining accuracy. Precision increases reliability and expands the range of designs possible.

Tools that aren’t optimized may move from hit to hit or arrange hits in a non-efficient manner. The resultant software is usually chaotic and messy. A path optimized by making use of neat rectangles and quick jumps could eliminate traverses that are unnecessary or minimize the overall length of the pathway.

VERICUT Force optimization cuts the cycle duration by eliminating unnecessary movement of the material or reducing the rate of feed when moving into or out of the material. It allows users to run CNC machines at a higher pace while maintaining best rate of feed. By minimizing machine and operator duration, operators can dramatically improve efficiency in production and decrease the cost of manufacturing. Utilizing the appropriate method of tooling, shearing force is delivered to the product most efficiently.